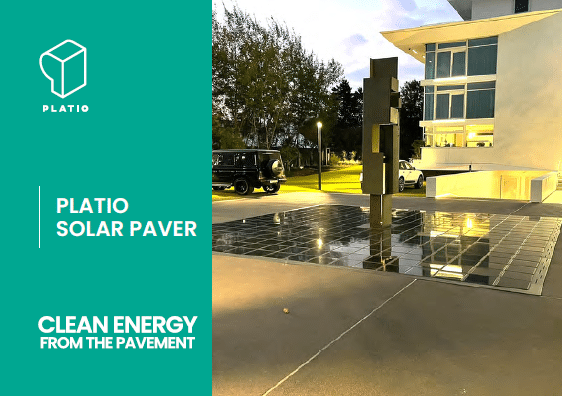

What is the product?

PLATIO Solar Paver is a paving block that is made out of a recycled (no virgin plastic material is used) plastic composite material and equipped with photovoltaic cells (PV-cells) that are integrated on tempered glass tiles. The electric system of PV-cells is operating on SELV (Safety Extra Low Voltage) voltage and the wiring is created with IP68 rated connectors.

How does the product operate?

PLATIO captures the solar energy radiated on walkable surfaces and converts it to electricity with the help of high-efficiency photovoltaic cells. The solarcells are integrated in glass tiles coated with anti-skidding surface. The solar radiation radiates through the glass tiles and reaches the photovoltaic cells that convert the radiation to electricity.

What is an on-grid system and how does it work?

An on-grid system is a photovoltaic system (PV) that connects to the electrical grid through a microinverter. The microinverter converts the generated DC (direct current) electricity into AC (alternating current), and the generated energy is then fed back to the power network, if not used locally. These PV-installations usually have to be authorized by the local energy utility provider company or the authority or body concerned.

What is an off-grid system?

An off-grid system is a system that does not connect to the electrical grid ensuring the operation of appliances independently from it. In case of an off-grid solar power system, the PLATIO Solar Paver is connected to a battery pack which if in need of AC current, connects to an inverter with output socket. These installations usually requires no authorization by the local energy utility.

How does an off-grid system work?

In case of a low voltage consumer (e.g. USB chargers, 12 or 24 V displays) there is no need for inverting the electric current to 120 or 240 volts AC with microinverters. In this case the batteries and the charge controllers are needed to be placed in a watertight box or inside of a building preferably not too far away from the PLATIO surface.

What if one of the tiles is under shadow? Does the whole System is out of production in that case?

Contrary to other technologies, in the case of PLATIO Solar Pavers, energy producing only stops on four cells (one unit) at once in case of shading factors such as: pedestrians, animals, vehicles, leaves etc. are on the surface. Due to the bypass diode integrated in the elements, hotpoint effect does not occour and the shaded unit does not heat up.

Is the energy production significantly less when the surface is dirty?

No, when the surface is contaminated with pollutants normally occurring (e.g. dust) the performance loss is about 3-7% depending on the situation in particular.

What is the material of the PLATIO Solar Pavement tiles? What anti-slipping certification does the product have?

The weight bearing layer of the product is made of a composite of recycled plastic and an additive of inorganic origin. The production of each PLATIO Solar Paver requires about 2 kgs of plastic waste. No new virgin plastic is used in the process.

What kind of plastic is used for the weight bearing layer?

Any kind of thermoplastic material can be used for the production of the recycled polymer composite that makes up the weight bearing layer of PLATIO Solar Paver. Currently it is made out of polyethylene coming from food industry waste. The waste material used in PLATIOs is otherwise non recyclable as it consists of several different types of polyethylene layers which is a normal structure in packaging technology.

How much plastic is used?

The production of each PLATIO Solar Paver requires about 2 kgs of plastic waste. No new virgin plastic is used in the process. The waste material used in PLATIOs is otherwise non recyclable as it consists of several different types of polyethylene layers which is a normal structure in packaging technology.

How is the plastic part made?

We use a unique kind of molding designed for this application. With this method, our goal is to radically reduce the price of the manufacturing and increase the amount of used plastic waste.

What is the advantage of the recycled plastic composite material?

The advantage of this composite material is that it has better hardness properties and longer lifespan than concrete. While high performance concrete (HPC) has a lifespan of max. 50 years, the composite material of PLATIO Solar Pavers keep their quality for min. 100 years.its tensile and compressive strength are much higher, and it absorbs much less water than the concrete used to make the tiles.

In addition to its technical advantages like formability and higher durability than concrete, this solution also contributes to sustainability. It is estimated that for every ton of cement produced, the process creates approximately a ton of carbon dioxide, all of which accounts for roughly 7 percent of the world’s carbon dioxide emissions. The production of cement for concrete and the CO2 emissions, coming from calcination, can be avoided by using PLATIO. It saves the environment from ~25 kg of greenhouse gas emissions per square meter.

Is the product technologically mature?

The first versions of PLATIO Solar Paver was made available to purchase in 2017. In 2021 the bottom part of the product has been redesigned based on the experience of international installations, thus creating an even easier installable system.

How PLATIO is made?

There are two main process streams in PLATIO Solar Paver manufacturing. First one is the plastic composite part production where recycled plastic waste is transformed into solid blocks of the product’s body-structure. Second process stream is the assembly where a sheet of layered glass including solar panels is mounted on the top of the composite block structure. Secondary sub-assembly steps like mounting the connections and soldering electronic parts are integrated into the main assembly.

Patent

The pending patent application is for the electronic system of the PLATIO Solar Paver units. The product also have design patent application in the USA and in the EU.

What tests has been carried out?

- Hydrochloric acid solution, 3% (v/v) UNI EN ISO 10545-13

- Potassium hydroxide solutions, 30 g/L UNI EN ISO 10545-13

- Hydrochloric acid solution, 18% (v/v) UNI EN ISO 10545-13

- Potassium hydroxide solutions, 100 g/L UNI EN ISO 10545-13

- Determination of impact resistance EN 14617-9

- Anti-slip property with ramp test with oil on surface DIN 51130

- Anti-slip property with ramp test with water on surface DIN 51097

- Anti-slip property pendulum test with dry and wet surface EN 13036-4

- For detailed result according to the upper standards ask our colleagues or distributors for the CE declaration of performance.

What anti-slipping certification does the product have?

‘Opal’ have:

- DIN 51097 “C” (water ramp test, scoring the highest available category)

- DIN 51130 “R12” (oil ramp test)

- EN13036-4 (pendulum test) Dry PTV mean value: 69, Wet PTV mean value: 58

‘Clear’ holds:

- EN13036-4 (pendulum test) Dry PTV mean value: 64, Wet PTV mean value: 24

Shock-protection certification?

We oblige our partners to always build our systems to be a SELV (Safety or Separated Extra Low Volatge) systems which means our system cannot cause harm in human health. Also we use inverters that has all the certifications – which results that our system is certified this way that it can not cause harms in electric systems as well.

Our recommended microinverters hold:

- UL 1741

- IEEE 1547

- IEEE 1547.1

- UL 62109-1

- IEC 62109-2

- CSA C22.2

Is it theft-proof, is vandalism a threat?

To this day no PLATIO unit has been stolen. The removing tool is sold only to our distributors.

For your reference see our hammer video:

https://youtu.be/DnPuSyT79h4.

Is glass safe?

The photovoltaic cells are integrated into durable, hardened glass tiles with anti-slippery coating on the surface, translucent enough to allow sunlight to pass through, and resistant enough to withstand truck traffic.

Loadability? Vehicles? Tonns? Traffic?

The PLATIO Solar Paver was primarily designed to be installed at pedestrian areas. The installations can withstand the weight of cars (max 3.5 tonns gross weight), but trucks and heavy-duty vehicles can NOT drive on the PLATIO solar paver installations. Maximum Load P (N) 145000 (14.5 tonns) per unit for brief periods of time (less than 10s). This means that the surface is capable for light vehicle traffic.

Is riveted winter tire allowed?

Scratches caused by studded winter tires might damage the surface of the PLATIO solar paver, thus it is not recommended to drive on it with such vehicles.

Is it possible to walk on the surface in high heels?

The glass tile of the PLATIO Solar Paver is scratch-resistant, so that cells can have perfect access to the sunlight.

Is it scratch resistant?

The glass tile of the PLATIO Solar Paver is scratch-resistant, so that cells can have perfect access to the sunlight.

Operating weather temperature range?

The operating weather temperature range is -40 to 50 °C. The surface of the pavement however can go up to 70 degrees in celsius.

Thermal expansion of the product?

Size change of the entire length is only around 1 mm on one unit. (From –30 to 70 degrees Celsius.)

Reflection parameters?

Radiation properties (EN 410)

- Light transmission: 0.91

- Light reflection outdoor: 0.08

- Light reflection indoor: 0.08

Solar energy characteristics (EN 410)

- Solar transmission: 0.89

- Solar reflection outdoor: 0.08

- Solar reflection indoor: 0.08

- (AVCP System: 3)

Reflection in terms of usage?

In case of the Clear product:

Reflections are shown on the surface but under the most lighting conditions this is no detectable disturbance for users.

In case of the Opal product:

No visible reflections.

Is the product waterproof?

The product is IP68 rated, this means in our case that the equipment is suitable for continuous immersion in water under up to 3 meters for 24 hours. For longer periods of time it can mean that water can enter but only in such a manner that it produces no harmful effects whatsoever on the users.

Can it be used in flooded areas?

We do not recommend to install in flooded areas, however 1-2 days of being underwater cannot cause harm in the units.

Saltwater corrosion?

According to the tests carried out below, no visible effects is shown after the following tests:

- Hydrochloric acid solution, 3% (v/v) UNI EN ISO 10545-13

- Potassium hydroxide solutions, 30 g/L UNI EN ISO 10545-13

- Hydrochloric acid solution, 18% (v/v) UNI EN ISO 10545-13

- Potassium hydroxide solutions, 100 g/L UNI EN ISO 10545-13

Wind?

The weight of the elements (6.5 kgs) makes it highly unlikely that the elements are lifted off and blow away in a typhoon event.

But if it is a serious concern, the elements should be placed in a cement bedding or fixed to a sleeper system with screws and fixing elements provided for the product if needed.

Safety directives?

For safety directives please read carefully the installation manual from page 3 to page 10.

Handling and storage directives?

For handling and storage directives please read carefully the installation manual from page 5.

Slipping safety?

Pleae consider that the two available surface treatments have the following certificates.

“Opal” have:

- DIN 51097 “C” (water ramp test, scoring the highest available category)

- DIN 51130 “R12” (oil ramp test)

- EN13036-4 (pendulum test) Dry PTV mean value: 69, Wet PTV mean value: 58

Clear holds:

- EN13036-4 (pendulum test) Dry PTV mean value: 64, Wet PTV mean value: 24

Opal product can be used in any installation no matter the rainfall conditions and winter climate or winter usage patterns.

Clear surfaces versions should be used where winter usage is not important or in the particular winter climate ice and snow are not big factors. It can be used even in such circumstances if not frequented walking surfaces are built with it. Take into consideration that these surfaces can be slippery when ice or snow is present on the surface but is not slippery when there is only water on the surface.

Shock protection

The system is operating on low voltage, so there is no chance of getting shocked. IP68 certificated connectors are applied to ensure the bulletproof connections between the units. We usually build our systems to be a SELV system which means our system cannot cause harm in anybody.

For total safety to human life we always build our systems to be certified SELV (Safety or Separated Extra Low Voltage) systems.

Is the surface hot in the summer?

The heat absorption of the PLATIO Solar Pavement is not different from the thermal features of regular paving solutions. In sunshine hours, the glass tiles of PLATIO do not warm up more than concrete or paving slab surfaces.

However since the thermal conductivity of the glass is good, its relative heat sensation may be higher than in the case of other pavings, so in the hottest of the summer barefoot walking on it is not pleasant to the skin.

Is a plan necessary?

In order to set the sufficient type and quantity of PLATIO Solar Pavers, PLATIO Solar Cables and other accessories (such as inverters or batteries), an electrical plan and a landscape design plan is preferred to be prepared by the implementor. Also it is useful for maintenance, monitoring or expansion of the surface in the future. Ask our colleague for help in need.

What kind of planning is needed?

PV-installations usually have to be authorized by the local energy utility provider company or the authority or body concerned. In order to apply for a permit it is most likely electrical plans will be necessary by a certified electrician or an electric angineer with the authority. We can provide you sample plans for your reference and also advise you in the planning.

It is advantageous if plandscape plans are also made in order to the location of conduits (protecting tubes for the cabling running to the microinverters) and cables must be clearly identifiable to the contractor.

A cabling schematics is also necessary for the easier installation, maintenance, monitoring or expansion of the surface in the future.

For help see installation manual.

What competencies are needed when istalling? Who can install?

PLATIO is designed to be rather easy to be installed – any contractor who knows how to install regular pavements can install the PLATIO system with the PLATIO installation manual, and in case he/she needs additional help, we are more than happy to provide assistance or contact you with our local distributor partner.

The laying of the base elements and cable connecting can be carried out by a non certified person. When connecting to the grid or batteries, or where the voltage is higher than SELV voltage only certified electrician is allowed to work.

We highly suggest you to get in contact with an electrical engineer or a certified electrician (whatever is obligatory in your area). We are more than happy to help you with the technical side, however electrical planning needs several inputs from the place where you would install the PLATIO-s and the other electronic devices, therefore we are unable to help with the complete electrical planning.

Installation time?

In case of a 10 sqm large system the installation usually takes about half days for a bricklayer and a helper. But this also depends on the layout of the cabling and also on the skillfullness of the installer. Keep in mind that foundations have to be made prior to the installation, especially in the case of concrete foundations.

Are temporary installations possible?

Yes, it is possible to make temporary installations. For temporary installations screw fixing is recommended, for which screws and fixing elements can be provided.

How is the wiring solved between the units?

For connecting the modules in series PLATIO Solar Pavers come with built-in cables and connectors. The cables are 2.5 mm2, 12 AVG. See the installation manual.

How does a usual PLATIO system look like?

For on-grid installations we offer the PLATIO On-grid System, which is a complete plug-and-play PLATIO system. The system contains:

- 18 units of PLATIO Solar Pavers,

- 1 microinverter

- and 1 microinverter cable.

- Q Relay

- Envoy system for monitoring the surface (up to 1000 18 pieces circuits)

The set of devices in PLATIO On-grid System is collected with no regards to the solar radiation conditions at the site of the given project. Usually a standard 18 units of PLATIO Solar Pavers are connected to a microinverter.

What kind of inverters am I supposed to use?

Any type of inverter can be used if the manufacturer certifies that on DC side (where people can interact with the surface) the voltage never under any circumstances exceed SELV voltage. Usually inverters that meet this condition are called microinverters. Our recommendation is to use Enphase IQ7PLUS microinverters.

How many microinverters do I need?

Usually 16-21 PLATIO units are connected to one line and this means about 2.5 m2 of PLATIO units to be connected together to obtain perfect MPPT tracking. However it is not a must, lower number of elements can be connected together but in this case it will not be the most possible efficient system.

Where do I place the microinverters?

In case of a regular outdoor installation microinverters are placed in a switch cabinet preferably close to the PLATIO pavement, usually within 50 meters.This Cabinet has to be connected with the surface by conduits and cables on the necessary places.

See installation manual for more details.

Is it safe to walk on a photovoltaic surface?

Yes it is. We require our pertners to build our systems to be SELV systems which means our system cannot cause harm in anybody also we use inverters that has all the certifications – which results that our system is certified this way that it can not cause harms in electric systems as well.

On what surfaces can we place PLATIO?

The construction of the substructure is completed by a method identical with that used in the case of generally constructed pavements/paving units. There is no need for any specific method during the preparation of the laying of the pavement. For more details, please find the PLATIO Installation manual.

Never use sand leveling layer, which can cause slight movement of the elments.

What kind of understructure is needed?

The construction of the understructure of PLATIO systems are completed by a method identical with that used in the case of generally constructed pavements/paving units. There is no need for any specific method during the preparation of the laying of the pavement. PLATIO units had been designed to cope with a wide variety of possible foundations. However it is necessary to emphasize: sand leveling layer is inadequate. The foundation has to be determined by the designer of the surrounding area if the project is not being implemented in the place of an already existing paved surface (in case of an existing pavement if the understructure is in good condition PLATIO can be placed on the top of it). Despite PLATIO can be placed on any kind of understructure we emphasize that the most durable understructure type is the solid concrete in most of the cases. Our company cannot take responsibility for damages caused by a faulty understructure. The regulations of the designer of the construction site should apply during the construction of the understructure.

Can PLATIO replace existing pavement?

Yes. If the PLATIO surface is being applied as a replacement of a paved surface, the first thing is to cut the existing pavement and pick up the paving elements. The leveling gravel (the layer between the pavement and the foundation) has to be smoothed and/or leveled. Do not place PLATIO on sand. If PLATIO is being built as a part of a new investment, the understructure needs to be implemented first, according to the plans of the designer responsible for the surrounding surfaces. Do not use sand leveling layer.

Is concrete foundation necessary? Is concrete foundation adequate?

In a number of applications concrete foundations are the most durable foundation type for a paving. It is the most suitable solution if vehicle traffic occurs on the paving. It is the preferred understructure on ramps and elevated slopes. For this method expansion joints are necessary; contact the manufacturer of the grout for the frequency of such joints (around 5 m). For certain polymeric based materials, it may be possible to omit the expansion joints. Please see installation manual.

What is a permeable foundation?

This solution is frequently used in pedestrian areas, parks and gardens and has the advantage of water permeability which is better for the nature and also has a better price-to-square-meter ratio. It is made of gravel. Please see installation manual from page 10 for more details.

What are the requirements for gravel / permeable foundation understructure?

If gravel foundation is being used as an understructure the following guidelines are recommended. It must be compressed no less than Trλ 95%. Both manual and machine-aided labor can be completed. In the proximity of pipelines, the regulations of the public utilities must be adhered to. Following the completion of the final surface, the understructure is built and compressed. The declination of the understructure and the pavement must be identical. Please see installation manual from page 10 for more details.

How does it fit in with the surrounding paving?

The height of the PLATIO units was chosen in order to fit the width of the ordinary pavements used in pedestrian areas. However sometimes thicker or thinner pavements are being used. In this case it is necessary to level the foundation and the leveling gravel or sand to bring the PLATIO and the other pavement to an equal height.

Always the PLATIO surface is laid first and the surrounding pavement is cut in order to fit the PLATIO surface.

Maintenance?

Basically, the PLATIO System has been designed in a way that it would not require relevant maintenance, because its basic function is to ensure walking surface, and as such it should operate even if exposed to extreme conditions.

The glass surface has to be checked visually about monthly. In case of contamination on surface (e.g.: mud), water and sweeper or brush is needed to remove it for better efficiency. This sort of cleaning has to be carried out monthly, except if the surface looks clean.

How can I monitor the systems?

Microinverters can also be connected to energy production monitoring devices. In case of Enphase microinverters, we recommend Enphase Envoy S monitoring devices. With these live monitoring is available both on PCs and mobile devices. If you have an already installed system contact your reseller or our customer service for more info.

In case of malfunction how do I know which PLATIO is malfunctioning?

The malfunctioning element can be identified by following these steps.

- Each line of PLATIOs (16-21 pieces) is connected to a communication gateway. This way we know which line malfunctions. Check the installation schedule to identify where is the faulty series is located in space.

- From the 16-21 elements in the line find the one in the middle of the circuit by looking up installation schematics.

- When the middle element in the series circuit is identified use the cover removing tool provided by our company and pull up the element.

- Measure voltage and current parmaters on the chosen element, do the same on the the series circuit before and the series circuit after the pulled up element. For this the first and last element may also have to be pulled up. If the pulled up element is malfunctioning change it to a new one. If not, next step.

- By now you have identified wether the series circuit before or after the middle element is faulty. Continue by pulling up the middle element of this series circle. (8-10 element)

- Continue this after you have found the malfunctioning element.

- The maximum required number of pulled up elements with this method is about 4.

- Finish by placing the elements back to their place, insert grouting back and sweep the surface to remove dust.

What to do if an element is broken?

Try to find out what caused the element to broke and take the necessary measures to prevent this from happening next time. For example if trucks heavier than 10 tonns parked on it. Examine the broken PLATIO unit. Since PLATIO elements top surface is made of hardened heavy duty glass the whole surface of the broken element will have a “cobweb nature”. The surface will remain in one piece and for a longer period of time no particles will fall out of the surface. Most likely even the broken element will continue to produce electric energy. The voltage is always below SELV level so even in case of a serious accident (inner parts of PLATIO units come to the surface) it is unable to cause harm in human life. However for aesthetic reasons and to to ensure long-term operation please contact your distributor for a spare PLATIO unit.

What happens if the inverter is broken?

We recommend to use Enphase microinverters. These products come with 25 years of warranty. In case of a broken inverter contact your installer or distributor who identifies the broken inverter through an online monitoring system and orders the spare part through this online interface. After the manufacturer shipped the product your intsller will replace the broken microinverter. Please note that since microinverters have the advantage of modularity, only around 2.5 m2 of your surface will not work during this repairing period. The other microinverters will work continuously.

Can EV station be stand–alone (off Grid with battery bank)?

Yes, it can be, but in this case the price of the batteries, the battery management, charge controllers and inverters are additional investment. With making the charging station on-grid this can be saved. The most efficient way to plant an EV charging station is to make it on-grid, because in case of no charging the produced electric current can be fed to the grid and vice versa at night endless number of cars can be charged.